Coatings for Aluminum

Primary Coatings

Our coatings are engineered to provide superior durability, corrosion resistance, and performance across demanding industries such as aerospace, military, automotive, and medical.

Anodize

Conventional anodize, or Type II anodize, is an anodic coating that converts the surface of the aluminum to aluminum oxide. This natural clear aluminum oxide layer provides excellent corrosion resistance, moderate durability, good adhesion for painting or bonding, and excellent coloring options. Coating thickness ranges from 5-25 microns or .0002 – .001 with only about 1/3 of that thickness as buildup per surface. Common applications are structural and architectural products, gage handles, door hardware, flashlights, fasteners, washers, dials, knobs, and mobile device housings.

Hardcoat

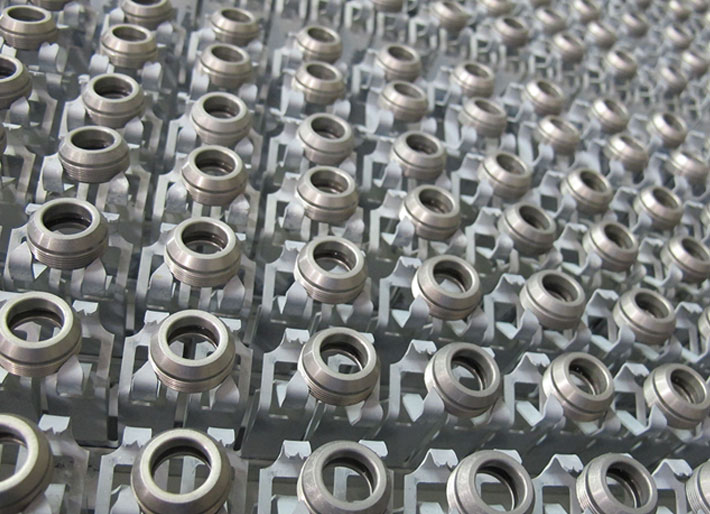

Hard anodize, or Type III anodize, is a variation of the conventional anodize process that yields highly wear-resistant coatings. While still providing outstanding corrosion resistance and acting as a good base coat, hardcoat is also extremely abrasion resistant and is commonly referred to as “file hard.” Hardcoat is naturally a darker coating and does not offer as many coloring options as conventional anodize. Coating thickness can range from 5 to 75 microns (.0002-.003) depending on alloy. Hardcoat properties exhibit a 50/50 penetrate/build up, that is 50% of the coating thickness will penetrate the surface and 50% will build up on the surface. Common applications include brakes, transmission components, sporting goods, cookware, firearms, tooling, fixtures, molds, and many more.

Chromate Conversion Coatings

Hexavalent and trivalent chromate conversion coatings on aluminum offer good corrosion resistance and bonding properties. Although they are not very durable they do maintain electrical conductivity allowing them to be used in applications where anodize or hardcoat are not suitable. These essentially immeasurably thin coatings are offered in the traditional hexavalent form or the trivalent form to comply with new environmental regulations. These coatings are often used in conjunction with anodize and hardcoat to maintain conductivity in certain areas while still providing protection.

Pixodize™

Pixodize is a breakthrough graphic anodizing process that goes way beyond the limitations of single color conventional aluminum anodizing processes. Pixodize opens up whole new possibilities for anodized or hardcoated products by infusing virtually any digital image into the coating. If you can picture it, we can Pixodize it. Just like traditional colored work the digital image will be integral to the anodize coating. With no additional buildup over the base anodic coating, it will not peel, flake, or chip off like other topcoat graphics. All this while meeting military, commercial, and industrial specifications make Pixodize the graphic process of choice.