200,000

Facility Square Feet

100,000,000

Pieces Completed Per Year

50+

Years in Business

FULL-SERVICE ANODIZER

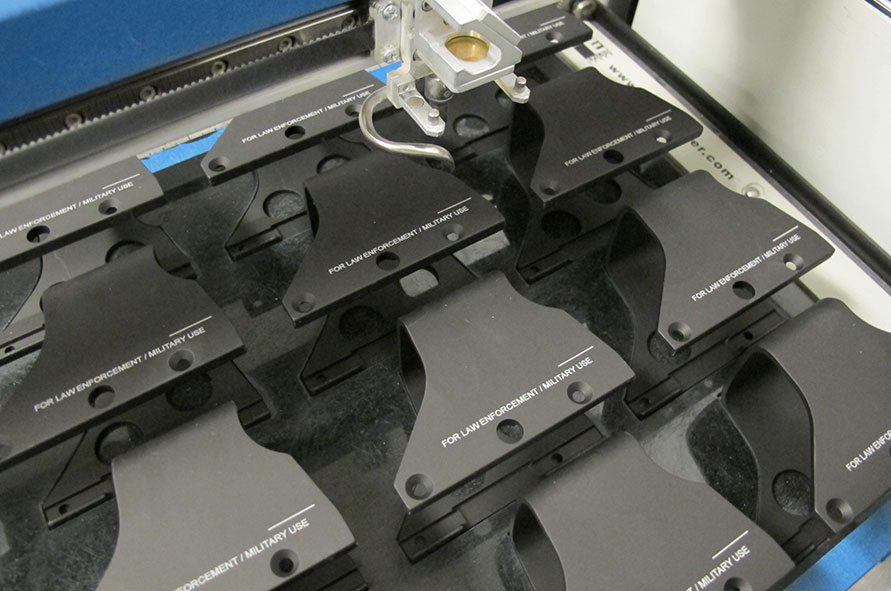

From our two state-of-the-art facilities in Detroit, Michigan, totaling over 200,000 sq. ft., International Hardcoat operates multiple automatic and semi-automatic processing lines to finish parts for industries ranging from automotive, aerospace, military, nuclear, and firearms to food preparation, medical, and recreational. Our capabilities include hardcoat anodizing, sulfuric anodizing, chromate conversion coating, and other advanced surface treatments, all performed to the highest industry standards.

With a commitment to precision, durability, and exceptional customer service, IHC supports both high-volume production and specialized custom work. Manufacturers as far away as Texas, California, and Washington State — and as close as Ohio, Illinois, and Indiana — seek out our expertise, quality, delivery, and competitive pricing, trusting us as a reliable partner in their manufacturing process. Our consistent investment in technology, process control, and staff training ensures we meet and exceed customer expectations every time.

Automotive

Aerospace

Military

Nuclear

Firearms

Consumer & Industrial Products

ADDITIONAL PROCESSES

– Centerless Grinding

– Laser Engraving

– Precision Masking

– Robotic Dry Film Lube

– Colors

– Chemical Etching

– Teflon (AnoLube)

– Robotic Paint

RELIABLE, INNOVATIVE & CUSTOMIZED SERVICE

Standards & Certifications

With ISO 9001:2015 Certification for quality systems, NADCAP Certification for the demanding aerospace industry. IHC meets and exceeds industry and community standards. We also hold a Federal Firearms License. Achievement of the coveted MISHARP certification from MIOSHA demonstrates our commitment to employee safety.